As you know proper planning and scheduling is of key importance for production companies. Dynamics 365 supports this process by optimization through the preparation of plans and schedules in the area of materials. The preparation of demand forecasts and the building of a flowchart on them is essential to ensure smooth production. Whole process depends on warehouse, logistics and shipment management. Efficient planning enables the calculation of delivery times and the creation of a realistic schedule. Production scheduling is based on the allocation of specific material resources, meeting specific guidelines, to carry out selected production orders, taking into account the specified time and in accordance with the adopted planning rules. The effect of scheduling is to define the dates of commencement and completion of production works. The goal of scheduling is, in the simplest terms, to efficiently use the available resources in specific time intervals.

Main thing is to realize what is production planning and scheduling?

The basics of production planning is to:

- determine the size of the production volume that should be performed in a specific time period.

By controlling and managing production process in terms of capacity, it is possible to ensure the best possible use of the production capacity at company. We can minimize production downtimes and maintain optimal stock levels. However, it should be borne in mind that the production plan should be a process integrated with the complex strategy of activities of the entire company.

The functionality of Dynamics 365 enables the prediction of various demand resources and takes into account data on the said demand and its coverage. The most important thing is to remember about the need to balance both of these areas.

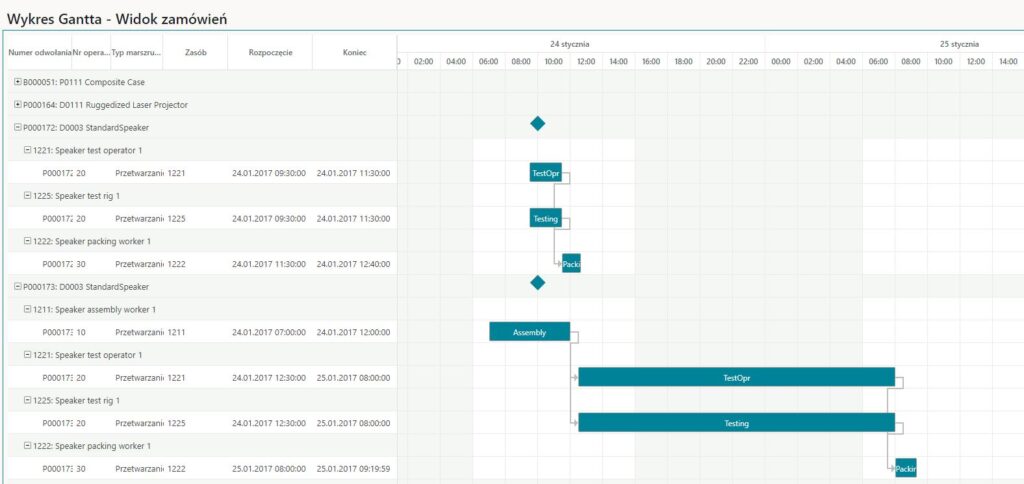

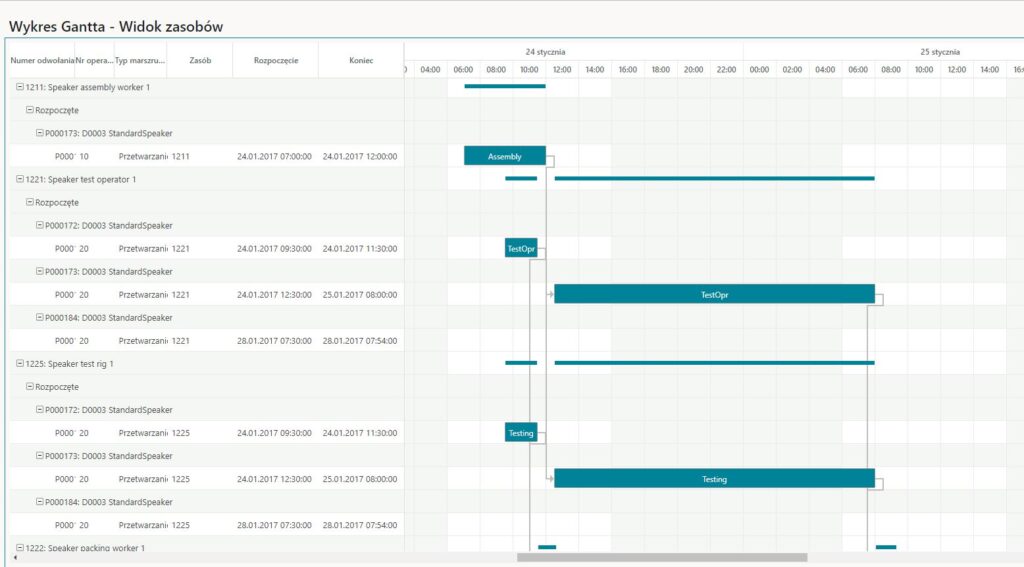

In the Microsoft Dynamics 365 software, you can plan production and the system allows you to make whole or certain parts of operations or tasks. The basic elements of operation planning include planning direction, resource capacity, and material optimization. By using the option of planning operations in the Microsoft Dynamics 365 system, it is possible to define a planning method and optimize the use of materials.

The Microsoft Dynamics 365 program enables:

- creating schedules for materials and semi-finished products

- scheduling machines, tools

- defining the planning direction, creating schedules forward or backward from a specific date

- preparation and modification of schedules

- delivery time definition using Availability to Promise (ATP) or Captable to Promise (CTP) method.

It is worth to remember that the planning of operations and tasks in Microsoft Dynamics 365 affects the master planning and the calculation of material requirements, taking into account such aspects as resources required for production, inventory, sub production and deliveries, as well as products that are already scheduled, released or started. Right now, as we know ale companies at the world have problem with planning their production because of broken supply chain processes, market demand is higher than production capabilities because of subcontractors have not got parts. In addition, the system is prepared to work with limited materials – in this case, planning is even more important in managing the entire production and guaranteeing its smoothness. It is worth to remember that the planning of operations and tasks in Microsoft Dynamics 365 affects the master planning and the calculation of material requirements, taking into account such aspects as resources required for production, inventory, subproduction and deliveries, as well as products that are already scheduled, released or started

The entire production management process using the ERP system is completed – in the case of Microsoft Dynamics 365 – with other modules, such as resource management, production routes, tracking and reporting of production processes. Microsoft Dynamics 365 enables a comprehensive approach to production control, which ultimately enables smooth operation of the entire production plant without the risk of problems with.